Original Company

Second Generation of Design (1932-1950s)

The Jacobs Wind Electric factory was located for over 20 years (until 1957) at 2111 Washington Ave. North in Minneapolis, MN. It is here that most of the production of the first Jacobs Wind took place. The machines produced here were 1.5 kW to 3 kW models, which, like their predecessors, were repeatedly refined.

Word of Jacobs Wind spread and it was known as the most dependable wind machine on the market. Over its first run, roughly twenty thousand Jacobs machines were produced and distributed worldwide. These machines could be seen everywhere from America to Canada, Africa, Asia, Europe, and even Antarctica. This last location was one of Jacobs’ early claims to fame, demonstrating the true resilience of the machine.

Admiral Byrd and Little America

In 1933 Admiral Richard Evelyn Byrd made his second expedition to Antarctica and took with him a 2.5kW Jacobs machine. This machine provided power for lights and radio broadcasting at Byrd’s Little America base camp. The expedition ended in 1935 and the wind machine was left along with most of the camp.

In 1947, Byrd returned to the location of his old base camp to find it mostly covered except for the a section of the once 70 ft radio tower sticking out of the snow with the Jacobs machine on top, its blades “still turning in the breeze.” The machine remained at the Navy’s base until it was taken down in 1955.

More Than Just Wind Machines

In addition to producing wind plants, Jacobs Wind Electric also sold batteries to store electricity and appliances to make use of the energy. In fact, everything from freezers to tornado alarms were designed and manufactured by the company. Welders, snow blowers, brush clearing saws and more also bore the Jacobs brand name.

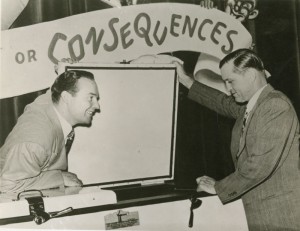

Freezers, designed to run on 32 volts or 110 D.C. and 110 A.C., were capable of holding a temperature for days without power. They made an excellent addition to many farms and even showed up as a game show prize on “Truth or Consequences” in the early 1950s. There were also Jacobs-brand irons, refrigerators, vacuum cleaners, waffle irons, air conditioners and even a line of marine products. Many of their appliances were manufactured by the Hamilton Beach Company (modified for direct current).

The necessity for snow removal in Minnesota preceded the need for a sturdy and powerful snow blower. Much like their wind plants, Jacobs brand snow blowers were effective in deep snow and held up to wear and tear. They were even used to clear snow out in driveways around the factory.

Jacobs Wind Machines also found many more uses than providing energy for farmhouses. A Jacobs machine might be seen powering a remote lighthouse or weather station. Some were used to provide power for telephone relay stations. In one of the more inventive uses of direct current, wind machines were used in 10 mile intervals along pipelines to produce a small reverse current flow to prevent corrosion on the steel pipe. Known as cathodic protection, the wind machine provided a charge to the pipeline in remote areas to reverse the current flows that otherwise were eating holes in the pipe.

The Decline of Small Wind Power

In 1935 The Rural Electrification Administration, REA, was created to bring electricity to rural areas. In 1936 Congress authorized rural electrification cooperatives or RECs. After World War II, the REA made large strides towards bringing centralized energy to rural locations in the west and midwest. By the 1950s, much of the need for small wind generators had disappeared. The electricity provided by power lines was less expensive and all maintenance was provided by the local REC. With no market left in small wind, M.L. and Joe closed the Jacobs plant in 1956.

This marked the end of an era. For over 25 years Jacobs machines had provided power to agriculture, telephone relay stations, pipelines, lighthouses and more. Jacobs Wind Plants continued to be used throughout 50s, 60s, and beyond, but the industry was gone. As a testament to their solid design and reliability, some of these machines from the first Jacobs Wind Electric Company remain in use to this day in various parts of the world while others are still sought out by small wind enthusiasts for refurbishing.

« Beginnings | Second Iteration »

Intro | Beginnings | Original Company | Second Iteration | Additional Info | Sources